Demand Driven Material Requirements Planning (DDMRP) is an advanced multi-echelon pull approach to plan inventories and materials that aims to manage the Supply Chain (SC) of an enterprise. This approach is grounded on the conservation and management of the flow of essential data. It also eases changes and recognises potential lack of supply in the manufacturing process.

Customers' demand always drives the SC in the first place, and supply shortages are often inevitable, no matter the size of the company. By using DDMRP, it is possible to control replenishment efficiently and on time by adding buffers to the supply stockpile and adjusting them when needed.

A significant shift in supply processes is essential.

Becoming demand-driven requires a significant change in the supply process, from the traditional methods of supply to the actual demand flow-centred method known as “position, protect, and pull”.

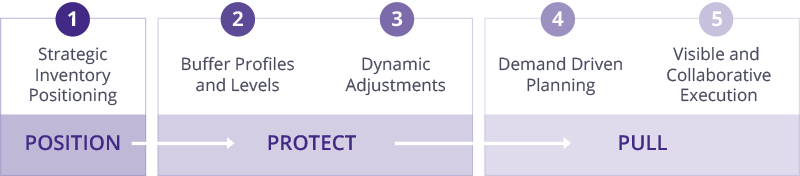

The DDMRP principles are “position, protect, and pull” and encompass five successive elements of DDMRP. The overall planning and operating approach of DDMRP is:

· Strategic inventory positioning pinpoints where to place the decoupling points.

· Buffer profiles and levels assess the protection level of the decoupling points.

· Dynamic adjustments calculate the protection level of the decoupling point too.

· Demand-driven planning outlines the daily operation of the system and is the process of supply order generation.

· Visible and collaborative execution is an open, visible way of supply order management.

Why does DDMRP have such a global impact on businesses?

· The supply planning models have not changed for decades if not centuries.

· DDMRP is shown to be valuable in many modern enterprises.

· The escalating difficulty of the modern supply chains makes DDMRP method essential for companies’ success.

· Product lifecycles are getting smaller whilst SC and product complication are ever-increasing.

· It has been proved to be valuable to plan inventories and materials.

· The centre of it is on a conscious approach, visual process performing, and the maximum transparency of procedures.

· It has been rapidly adopted by many leading companies all over.

· It is a cutting-edge and highly-efficient solution that allows controlling your SC.

· It improves productivity, customer service, business flow, and cuts expenses.

· It makes a company build up more closely to real market requirements and stimulates much smarter- faster decisions and actions at the planning and execution level.

DDMRP eliminates the need for many workarounds

Changes to the system might call for change to the spreadsheets and personal databases, but often there is not enough time or know-how to make the appropriate changes. Stay firm enough to avoid any intervention from seniors or corporate managers and make sure everyone is operating under the same principles already established by the use of DDMRP.

SUMMING UP: by orchestrating inventories with demand, and acknowledging the realities of the incoming Supply Chain, DDMRP right-sizes inventories in materials

.

The following figure explains these elements, their sequence, and how they link up to the principles of "position, protect and pull."

It is more necessary today than ever.

Dave Food

Prophetic Technology

Subscribe to our emails & exclusive free content.