The Control Tower concept is gradually becoming well-known in the Supply Chain Management community; its industry's common advantage is 'visibility,' as it represents an attempt to make the outside SC environment visible to the company. They are not physical places, but useful tools to visualise and synchronise your SC processes.

Because SC is today a globalised-outsourced process, it results in exponential risks all through the vast SC; for this reason, advanced Control Towers are an attempt to combat these likely threats with visibility.

They evolved to become basic-winning strategies that operate Predictive-Prescriptive Analytics qualities through Artificial Intelligence (AI). By establishing an ecosystem that meets transparency, organisations gain visibility to diminish possible risk issues and secure data to manage orders better.

Lack of visibility, incompetence, and distribution of drivers in last-mile delivery are demanding challenges to deal with. Therefore, organisations must integrate edge-technology and adopt innovative strategies to keep being significant in this competitive market. Like the autonomous agent, multiparty networks, and advanced analytics, edge technologies make it easier to enhance and automate your SC.

The advanced-intelligent Control Tower capabilities

In recent times, the advanced-intelligent Control Tower becomes the centre for visibility, decision-making, and action, built on real-time analytics; this strategy brings business value. Hereafter some SC Control Tower capabilities:

· End-to-end visibility among SC partners, encompassing suppliers, contract manufacturers, transportation carriers, third-party logistics.

· It is a cognitive-self-correcting SC tool with decision-making and Machine Learning.

· It is autonomous decision-making and control to boost productivity.

· It organises, monitors, and controls conclusions, and implements roles across the company to boost the whole network.

· Continuous incremental planning and executions are advantages of a Control Tower.

· It diminishes inventory and logistics expenses.

· It makes the best use of on-shelf availability, service levels, and resilience to disruptions.

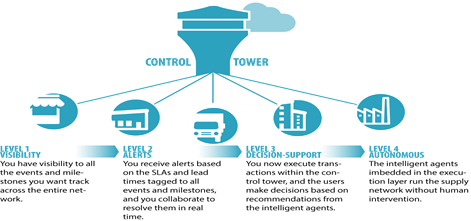

· It counts on four levels of maturity.

· It applies Predictive Analytics to work out issues in advance.

· It put into operation Prescriptive Analytics to make recommendations.

· It works as an approach to establish commitment among commercial parties.

· It coordinates companies, co-workers and processes, suppliers, logistics, transportation and more, to work in sync in real-time to provide end-consumers.

Practical capabilities

· It counts on real-time tracking by sharing information in real-time.

· Early warning alerts to handle exceptional management of your SC disruptions in advance.

· It makes order fulfilment simple to put together, flexible-secure- reliable order data incorporation.

· It enhances a transport management plan, optimises shipments, and streamlines communication among parties.

· It supports Inventory Management reduction in shortages/stock-outs and improved warehouse and transport inventory.

· It provides visibility monitoring in real-time, fully SC transparency for improved service levels and traceability.

· Freight-settlement-expending costs go down with truthful-reliable billing, audit, and payment activities.

· Request and deviation management – increase in on-time shipments and maximised service levels through request tracking and incident handling.

CONCLUSIONS: SC Control Towers attempt to tackle the lack of visibility and possible escalating risks in our extended SC. Through a Digital SC, it will enable full visibility among SC partners. It is a challenging capability that must be part of everyone's Supply Chain strategy.

Prophetic Technology

Subscribe to our emails & exclusive free content.